Control 글 편집 글 편집 (이전 에디터)

RecurDyn/Control gives the ability to co-simulate RecurDyn with Matlab Simulink, AMESim, SimulationX and other control software. This toolkit enables the prediction of the dynamic behavior of the product, including PID controllers, actuators, hydraulic systems and various control algorithms.

- Co-simulation with Matlab Simulink

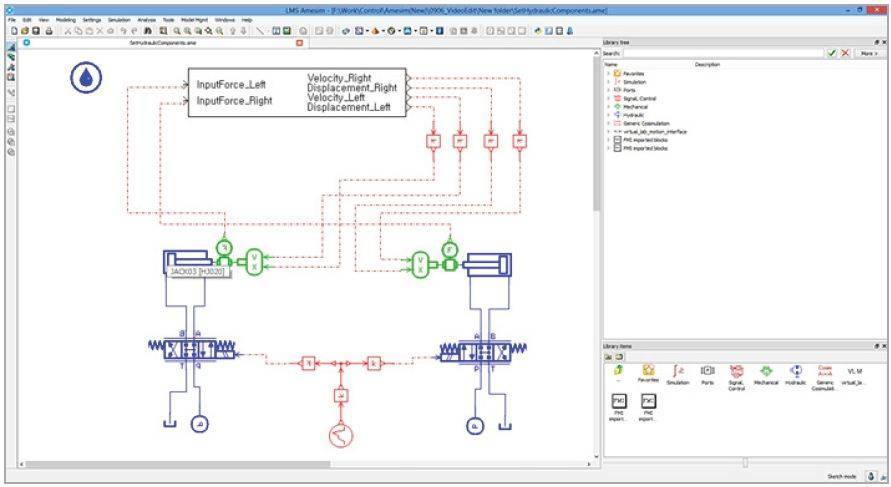

- Co-simulation with AMESim for hydraulic systems

- Co-simulation with other control software using FMI (Functional Mock-up Interface)

Accurate and robust models of a mechanism are required for the design and parameter optimization of control system algorithms, as well as their reliability verification (mechatronics simulation). RecurDyn provides a diverse set of tools to analyze mechanism models coupled with the control system algorithm such as PID controller.

RecurDyn provides a special interface for co-simulation with the MATLAB/Simulink that is widely used for mechatronics simulation. In addition, RecurDyn supports FMI to incorporate the use of AMESim and Modelica-based applications.

RecurDyn/CoLink allows for fast and accurate control system analysis through the deep integration of the control simulation code with RecurDyn’s dynamics solver.

A robot's controller can be validated using RecurDyn.

Co-simulation with Matlab / Simulink

RecurDyn/Control includes an interface for co-simulation with MATLAB/Simulink.

Co-simulation between Matlab Simulink and RecurDyn allows mechanical systems that contain controller and drive systems, such as PID controllers and motors, to be analyzed using mechatronics simulation.

Simulink Interface:

- RecurDyn/Control includes an interface which allows it to utilize a realistic dynamic model of RecurDyn in a MATLAB/Simulink model.

- It is possible to use a RecurDyn model including contacts or flexible bodies as well as various joints or forces in the model created by Simulink.

- A RecurDyn model can be integrated with a Simulink model using a UI which easily creates an S-Function for the RecurDyn Plant model.

-

For example, a Simulink PID controller model can be co-simulated with RecurDyn.

RecurDyn and Matlab Simulink Co-simulation Demo (RecurDyn model with a PID Controller)

FMI (Functional Mockup Interface) for Co-simulation

RecurDyn supports FMI, a standard interface based on Modelica, and co-simulation with applications that support FMI

Support for co-simulation with AMESim, SimulationX and Simplorer

AMESim hydraulic system model can be co-simulated with RecurDyn using FMI

Benefits

- Controls engineers can efficiently test control algorithms (such as PID controller) early in the design process with highly nonlinear dynamic models for mechatronics simulation.

- Mechanical systems may include control systems (whether electronic, hydraulic, etc.)

- The mechanical engineer and the controls engineer can join their independent design models.

- Controls engineers may struggle to develop robust controllers early in the design process. because of the difficulty in constructing nonlinear dynamic models within controls software such as Matlab Simulink, AMESim, SimulationX, Dymola. These difficulties can be avoided by developing the mechanical model in RecurDyn and, using RecurDyn/Control to interface with the controls software.

Process

- All mechanical components and constraints are modeled with RecurDyn.

- The control algorithms are modeled using the control application such as MATLAB Simulink, AMESIm, Dymola, SimulationX.

- RecurDyn/Control manages the co-simulation of RecurDyn and the control application.

- Plant outputs are passed from RecurDyn to the control application at a constant sampling rate.

- Control outputs are passed from the control application to RecurDyn at a constant sampling rate.