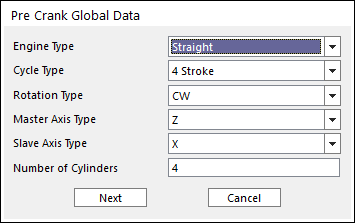

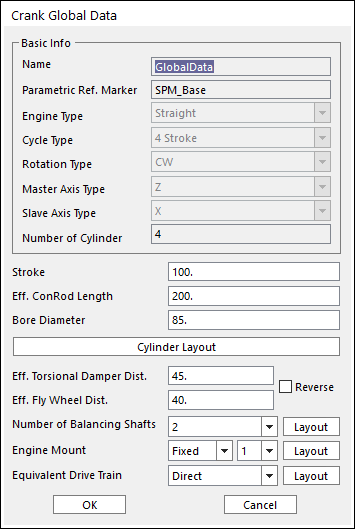

1. Click the Data icon of the Crank group in the Crank tab. The user can see Pre Crank Global Data Dialog.

Figure 1 Pre Crank Global Data dialog box

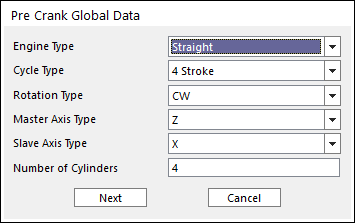

•Engine Type: There are three kinds of Engine type. They are Straight, V type and Horizontal type.

Figure 2 Types of engine

•Cycle Type: Select an engine cycle 2 or 4 stroke. In the 2 stroke engine system, a process of 'Suction – Compression – Explosion – Exhaust' occurs during 1 rotation of Crank Shaft. However, in the 4 stroke engine system, the process occurs during 2 rotation of Crank Shaft. So, the Cycle Type is related with Firing Angle and Gas pressure profile.

•Rotation Type: Select the crankshaft’s direction of rotation, which is CW (clock-wise) or CCW (counter-clock-wise). And then the crankshaft’s direction of rotation is decided.

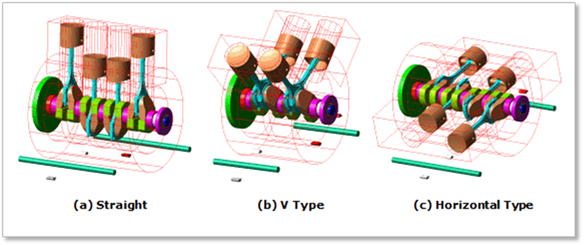

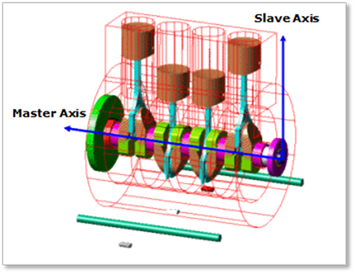

•Master Axis Type: Select the axis which direction can be the rotating axis of crank shaft.

•Slave Axis Type: Select the axis which direction can be the cylinder's direction.

Figure 3 Master & Slave Axis of Crank System

•Number of Cylinder: Enter the value of number of cylinders that can be created.

2. Previous defined values are the basic information to create the crank system. After this data is confirmed, each value is unchangeable. So, if Next is clicked, warning message is displayed.

3. After that, the Crank Global Data Dialog is opened.

Figure 4 Crank Global Data dialog box

•Name: Means that the values the user entered are defined in Global Data

•Parametric Ref. Marker: Checks the parametric marker for crank system. SPM_Base controls the whole system. It cannot be modified.

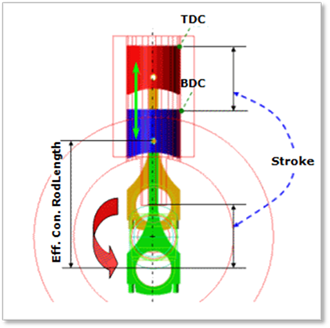

•Stroke: Is a distance between TDC (Top Dead Center) and BDC (Bottom Dead Center). If the user changes the value of stroke, rotation diameter of crank shaft pin is changed to be same with the value of stroke.

Figure 5 Stroke of engine

•Eff.Con. Rod Length : Defines the distance between the center point of crankshaft's pin body and piston pin.

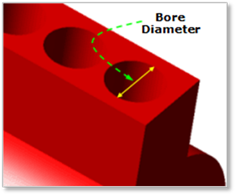

•Bore diameter: Defines a diameter of cylinders. If the user changes this value, a piston head diameter is also changed. Because the values are defined by SPV_Cylinder_Diameter_i which is Special Parametric Value.

Figure 6 Bore Diameter

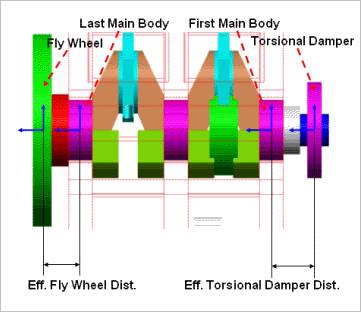

•Eff. Torsional Damper Dist.: Defines a distance from the center point of the first main body of crank shaft to the center of a Torsional Damper.

•Eff. Fly Wheel Dist.: Defines a distance from the center point of the last main body of crank shaft to the center of a Fly Wheel.

Figure 7 Eff. Torsional Damper Distance&Eff. Fly Wheel Dist

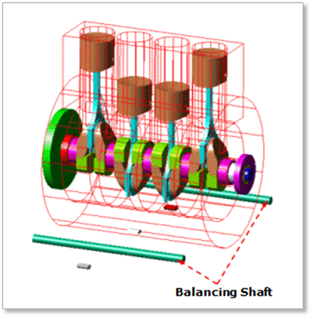

•Number of Balancing shafts: Selects the number of

balancing shafts in Figure 4.

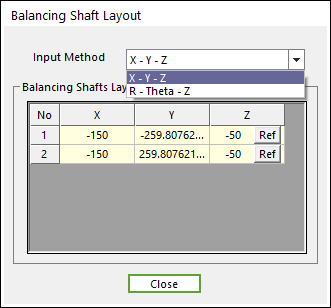

•If the user clicks Layout of balancing shaft in Figure 4, Balancing Shaft Layout Dialog is opened. In this dialog box, the user can confirm and define the position of SPM of each Balancing Shaft. There are two kinds of Input method. One is the X-Y-Z Input Method. The other is the R-Theta-Z Input Method.

Figure 8 Balancing

Shaft Layout dialog box

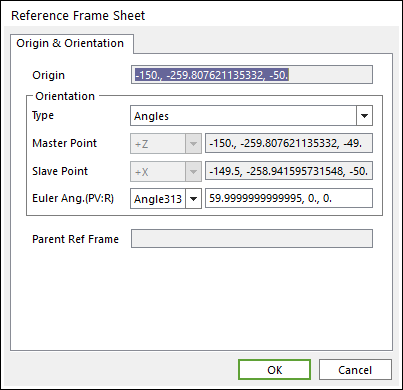

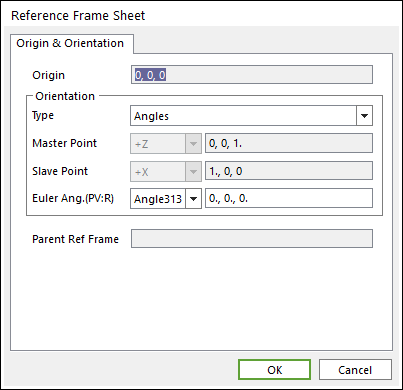

•If the user clicks Ref in Figure 8, the user can confirm the information of SPM which is reference maker of Balancing Shaft, such as the name of SPM, the origin of SPM and the orientation of SPM.

Figure 9 Reference Frame dialog box

Figure 10 Number of Balancing Shaft

•Engine Mount: The user can mount the engine block to the ground using Fixed Joint or Bushing Force.

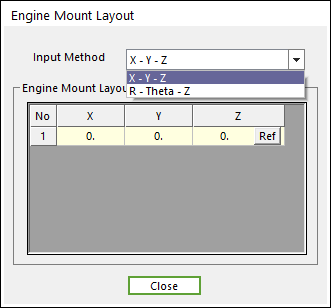

•If the user clicks Layout of Engine Mount in Figure 4, Engine Mount Layout dialog box is opened. In this dialog box, the user can define the position of SPM of Engine Mount. There are two kinds of Input method. One is the X-Y-Z input method. The other is the R-Theta-Z Input method.

Figure 11 Engine Mount Layout dialog box

•If the user clicks Ref, the user can confirm the information of SPM which is reference marker of Engine Mount, such as the name of SPM, the origin of SPM and the orientation of SPM.

Figure 12 Reference Frame Sheet dialog box

•Equivalent Drive Train (EDT): In whole engine system, when

a crank shaft is rotated, resisting force is generated against Crank

Shaft caused by EDT (Equivalent Drive Train) which is

connected with Crank Shaft. The EDT can include transmission,

clutch, drive shaft, chain, wheel, tire and so on. It is represented as

equivalent moment of inertia and stiffness including speed ratio. In general,

three types of EDT are used in automotive system. These are

direct-drive, gear-drive and belt-drive.

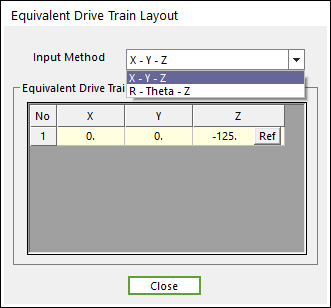

•If the user clicks Layout of Equivalent Drive System in Figure 4, EDT Layout Dialog is opened. In this dialog box, the user can define the position of SPM of EDT. There are two kinds of Input method. One is X-Y-Z input method. The other one is R-Theta-Z Input method.

Figure 13 Equivalent Drive Train Layout dialog box

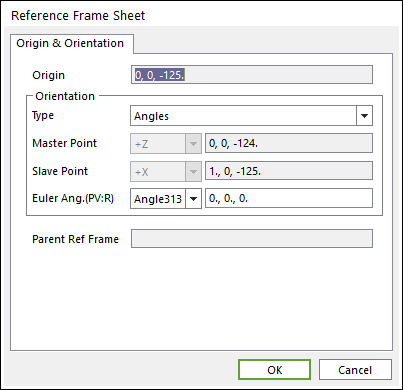

•If the user clicks Ref, the user can confirm the information of SPM which is reference marker of EDT, such as the name of SPM, the origin of SPM and the orientation of SPM.

Figure 14 Reference Frame Sheet dialog box

4. After setting all parameters, click OK.

5. The user can define the geometric and connection information using the Component Builder.