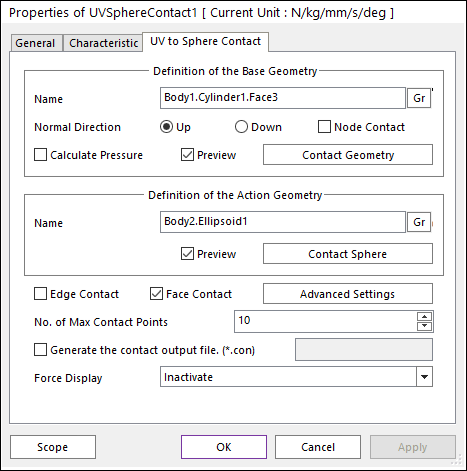

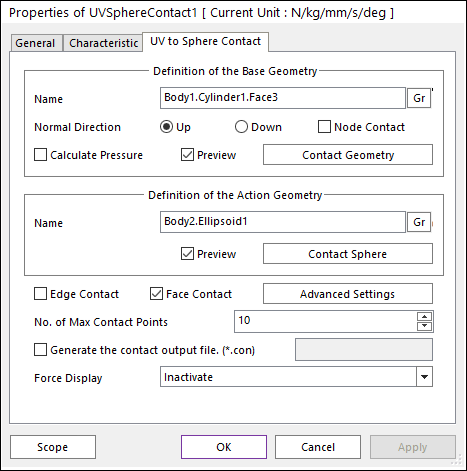

Figure 1 Properties of UVSph dialog box

•Definition of the Base Geometry

•Name: Defines the name of base geometry. The base geometry can be modified from the Working Window by clicking Gr.

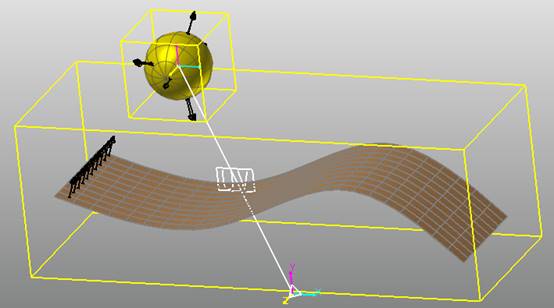

Figure 2 Preview of the normal directions, contact patches and nodes.

•Normal Direction: Defines the normal direction of a base geometry for a contact as shown in figure 2.

o The contact is available in the specified direction.

o As selecting “Up” or “Down”, the user can change the contact direction of a base geometry.

o If this page is activated, the normal direction is automatically shown on the Working Window.

•Calculate Pressure: Calculates contact pressure for surface type geometry. Contour file is created when this option is activated.

o The calculated pressure result is calculated on each node. Pressure is calculated by an area and a force projected to the node. The force value for pressure is calculated by the forces that occur around the node. And the area value for pressure is calculated by the patches and size of the patches around the node.

•Preview: If this option is checked, the patches making the contact surface are shown on the Working Window as shown in the above figure.

•Node Contact: If this option is checked, the contact force by the base node is calculated.

•Contact Geometry: Accesses the Surface Patch dialog box as shown in the below figure.

Figure 3 Surface Patch dialog box

o Surface Name: This shows the name of the selected base contact geometry.

o Bounding Buffer Length: This value is used when the contact pre-search is performed with base and action bounding box. The bounding buffer length defines the offset length of bounding box compared to the real bounding box as shown in the below figure. This value is automatically calculated but can be modified by the user. Additionally, if you click Cal., this value is updated with the recommended default value.

o Number of Patch (U): This value defines the number of quad patch in U direction in UV surface.

o Number of Patch (V): This value defines the number of quad patch in V direction in UV surface.

o Cubic Cell Size: Shows the number of cubic cells dividing a contact bounding box in each direction. This value is automatically calculated but can be modified by the user.

•Definition of the Action Geometry

•Name: Defines the name of action geometry. The action geometry can be modified from the Working Window by clicking Gr.

•Preview: If this option is checked, the contact direction is shown on the Working Window as shown in the above figure.

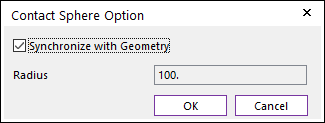

•Contact Sphere: Accesses the Contact Sphere Option dialog box as shown in the below figure.

Figure 4 Contact Sphere Option dialog box

o Synchronize with Geometry: If this option is checked, Radius is automatically defined with radius of action sphere. If this option is not checked, the user can modify the Radius.

o Radius: Defines the radius of an action sphere.

•Edge Contact: If this option is checked, the contact force by the base and action sphere is calculated.

•Face Contact: If this option is checked, the contact force by the base patches and the action sphere is calculated.

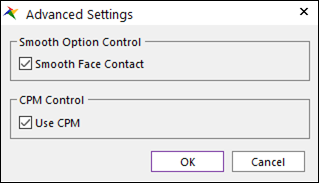

•Advanced Settings: Accesses the Advanced Settings dialog box as shown in the below figure.

Figure 5 Advanced Settings dialog box

•Smooth Face Contact: In the case of Surface type as Geometry type, this option is activated. If this option is checked, the smooth contact algorithm is applied in sphere-to-face collision pattern and the corresponding face is smoothed by using bi-cubic Hermite surface equation. The bi-cubic Hermite surface equation is generated by using the node position and tangent vectors in U and V direction which is calculated internally in RecurDyn solver.

•Use CPM: CPM is the abbreviation of Consistent Penetration Method. If this option is checked, the contact force at each contact point is divided by the total number of contact points. As a result, although user uses different facet or element size for the geometry, total contact force magnitude will be remained in similar level. This means that the user does not need to change the contact stiffness or contact damping parameters when the user uses different mesh or different faceting values for the same geometry. On the other hand, if this option is unchecked, the contact force is applied for the all contact points with given contact parameters.

•No. of Max Contact Point: Defines the number of max contact point for output. User can define this value from 1 to 5000. This value only affects Force Display and RPLT data about contact points.

•Generate the contact output file(*.con): When this option is checked, RecurDyn creates the contact output file based on the contact output reference. For more information, click here.

•Force Display: Graphically displays the all contact force vectors (the sum of the normal and tangential contact force) at each contact point up to the “No. of Max Contact Point” as shown in the below figure. For more information, click here.