By fault in making and assembling the gear, the problems such like transmission error, noise and load concentration can be occurred. In order to reduce or optimize these gear problems, the gear tooth modification is applied along the flank or profile. Therefore, to simulate the dynamic behavior of gear modification effect, RecurDyn/Gear toolkit supports crowning, helix slope and tip relief gear modification. And also, it is allowed to define the left/right gear flank modification individually. So, user can analyze an asymmetric gear effect, too.

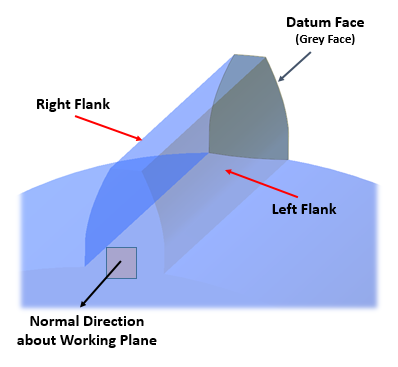

Definition of Right/Left Flank of Gear Tooth

The right flank (or left flank) is defined by Figure 1. The definition of right-hand/left hand tooth flank are defined with respect to datum face and that are in accordance with ISO 21771.

Figure 1 The Definition of Right/Left Flank

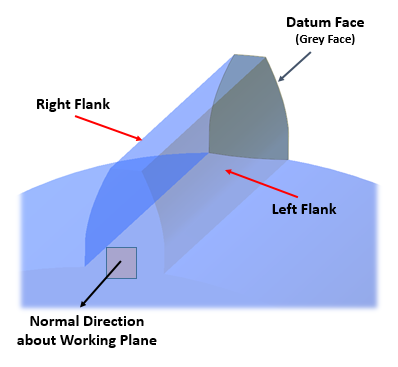

Figure 2 Modification dialog box

•Crowning Effect

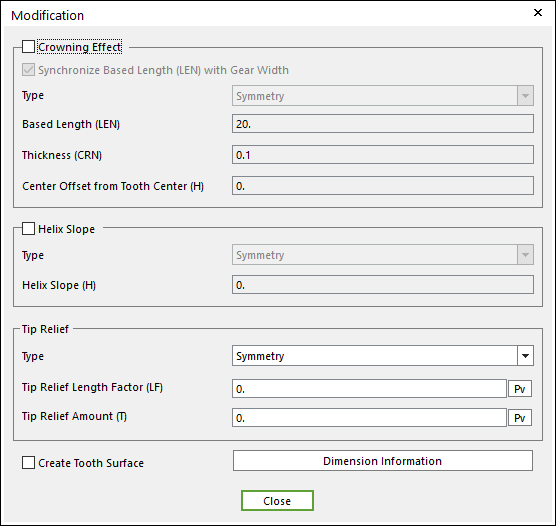

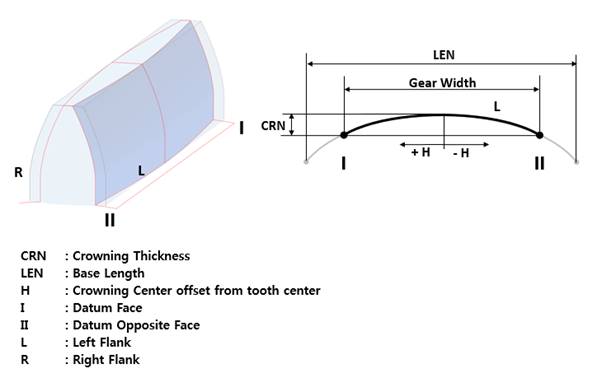

Crowning is the continuously increasing relief on the flank line from a common defined point of the main geometry, symmetrically in the direction of both ends of the tooth. And, crowning function should be applied to create the extruded gear tooth by using a quadratic curve which is defined three parameters such as LEN, CRN and H as shown in the Figure 3. Especially, this crowning modification helps to solve the edge loading problem of gear tooth.

Figure 3 The Definition of Crowning Effect

•Crowning Effect: If this option is checked, crowning effect function will be activated.

o Synchronize Based Length (LEN) with Gear Width: The LEN value is set as same value of Gear Width. If the user wants to define the LEN as your own value, check off the option. And then, you can input the LEN value to the input field.

o Type: If the user wants to make asymmetrical crowning effect to the gear tooth, change the Type from Symmetry (default) to Asymmetry. Then, the user can input the Left/Right crowning effect values individually.

o Based Length (LEN): Enters the based length of tooth.

o Thickness (CRN): Enters the crowning thickness of tooth.

o Center Offset from Tooth Center (H): Enters the offset value form tooth center.

•Helix Slope Effect

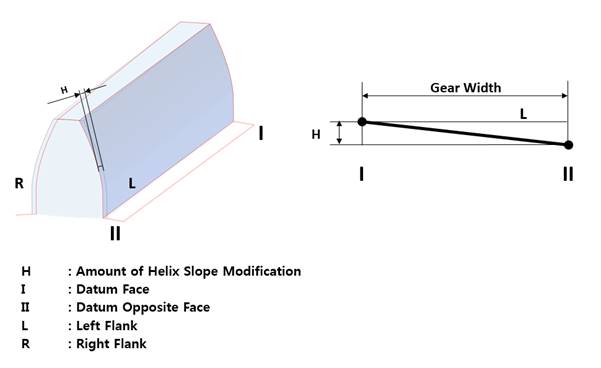

Helix Slope modification is the continuously increasing removal of material from datum face to opposite face as shown Figure 4. Especially, helix slope modification is applied to get a uniform load distribution to the face width to increase the gear lifetime.

Figure 4 The Definition of Helix Slope Effect

•Helix Slope: If this option is checked, helix slope function will be activated.

o Type: If the user wants to make asymmetrical Helix Slope effect to the gear tooth, change the Type from Symmetry (default) to Asymmetry. Then, you can input the Left/Right Helix Slope effect values individually.

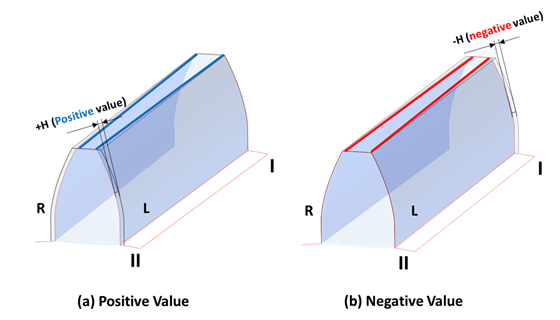

o Helix Slope (H): Inputs the helix slope value to the input field. Also, in the case helix slope effect, it is available to change the helix direction according to helix slope value. If you input the positive helix slope value, the helix slope modification will be the continuously increasing removal from datum face to opposite face as Figure 5(a). However, if you input the negative helix slope value, the helix slope modification will be the continuously increasing removal form opposite face to datum face as Figure 5(b).

Figure 5 Helix Slope Effect according to Helix Slope value

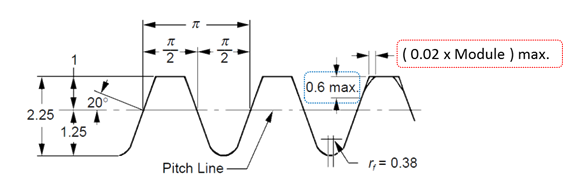

Tip Relief is the continuously increasing reliefs of the transverse profile of the main geometry from defined points in the direction of the tip as shown Figure 6. Especially, tip relief modification is applied to reduce Transmission Error for high loaded gears.

Note: In order to apply these values, The number of Tip Relief Arc should be defined in Tooth Profile page. For more information, click here.

Figure 6 The Definition of Tip Relief Effect

•Type: If you want to make asymmetrical Tip Relief effect to the gear tooth, change the Type from Symmetry (default) to Asymmetry. Then, you can input the Left/Right Tip Relief effect values individually.

•Tip Relief Length Factor (LF): Enters the factor to define Tip Relief Length by Gear Module multiply (L=M x LF).

•Tip Relief Amount (T): Enters the Tip Relief Amount.

The maximum of Tip Relief Amount & Tip Relief Length Factor are limited as like below Figure 8. So, tip relief amount must be less than 0.02 x Gear Module and tip relief length factor must be less than 0.6 factor.

Figure 7 The Limitation of Tip Relief Amount & Length Factor

•Create Tooth Surface: If this option is checked, a face surface is created for the gear tooth. It is very useful to define a contact entity.

Note

It is only available to define the gear tooth modification functions to spur and helical gear. Also, when user defines gear tooth modification such as Crowning and Helix Slope to spur and helical gear, user can only use 3D contact (Surface to Surface contact) or 3D Contact R (Solid Contact) between the gear pair.