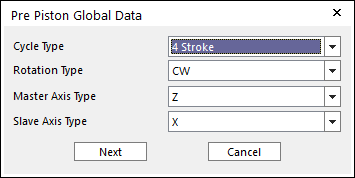

7. Click the Data icon of the Piston group in the Piston tab. The user can see the Pre Piston Global Data Dialog.

Figure 1 Pre Piston Global Data dialog box

•Cycle Type: Selects the engine cycle 2 or 4 stroke. Cycle Type is related with Firing Angle and Gas pressure profile.

•In the 2 stroke engine system, a process of 'Suction – Compression – Explosion – Exhaust' occurs during the 1 rotation of crank shaft.

•In the 4 stroke engine system, the process occurs during the 2 rotation of crank shaft.

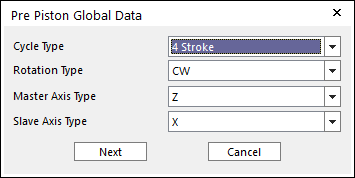

•Master Axis Type: Select the axis which direction can be the rotating axis of crank shaft.

•Slave Axis Type: Select the axis which direction can be the cylinder's direction.

Figure 2 Master & Slave Axis of Piston System

•Number of Cylinder: Enter the value of the number of cylinders that can be created.

8. Previous defined values are the basic information to create the piston system. After these data are confirmed, each value is unchangeable. So, if Next is clicked, the warning message is displayed.

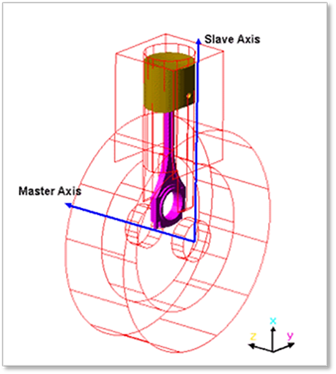

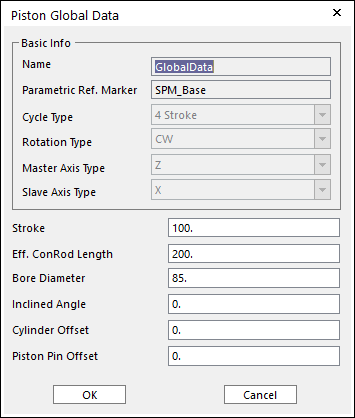

9. After that, the Piston Global Data Dialog is opened.

Figure 3 Piston Global Data dialog box

•Name: Means that the values the user entered are defined in Global Data.

•Parametric Ref. Marker: Checks the parametric marker for crank system. SPM_Base controls the whole system. It cannot be modified.

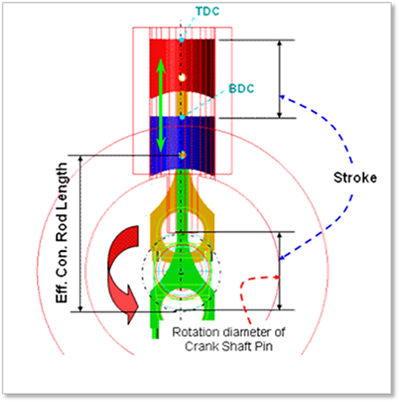

•Stroke: Is a distance between TDC (Top Dead Center) and BDC (Bottom Dead Center). If you change the value of Stroke, rotation diameter of Crank Shaft Pin can be changed to be same with the value of Stroke.

Figure 4 Stroke of an engine

•Eff.Con. Rod Length: Is the distance between the center point of crankshaft's pin body and piston pin.

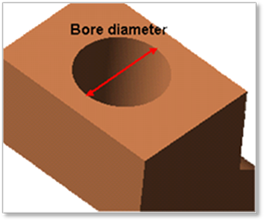

•Bore diameter: This value is a diameter of cylinders. If you change this value, a piston head diameter is also changed. Because the values are defined by SPV_Cylinder_Diameter_i which is Special Parametric Value.

Figure 5 Bore Diameter

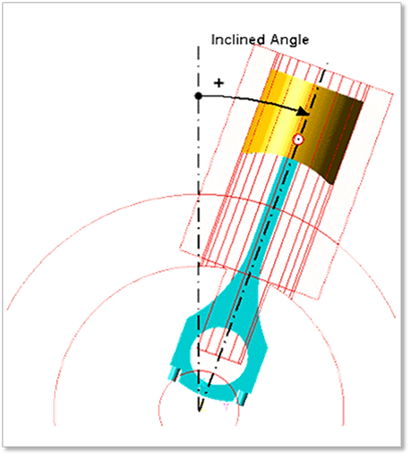

•Inclined Angle: Please refer to the below Figure.

Figure 6 Inclined Angle

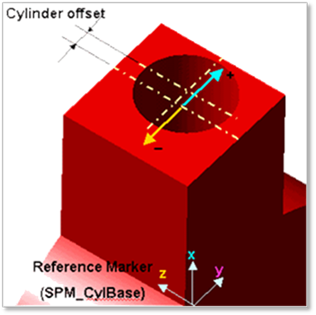

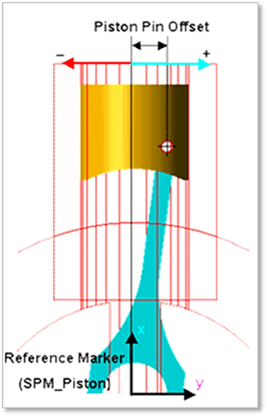

•Cylinder Offset & Piston Pin Offset: Please refer to the below Figures.

(a) Cylinder offset

(b) Piston pin offset

Figure 7 Cylinder / Piston pin offset

10. After setting all parameters, click OK.

11. The user can define the geometric and connection information using the Component Builder.