Plotting a transient Campbell diagram requires the RPM against time value or tachometer data and the time measurement signal. More specifically, the RecurDyn’s post-process requires three types of data: time, RPMs, and signal, or time, tacho data, and signal. In this process, the number of data entries for each type of data must be the same.

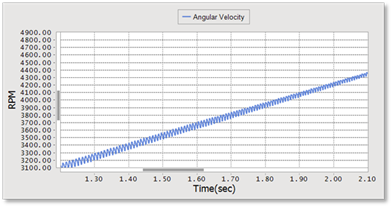

•RPM Data

The RPM data is the system status data that increases or decrease against time. Smaller RPM variations are better.

Figure 1 RPM data

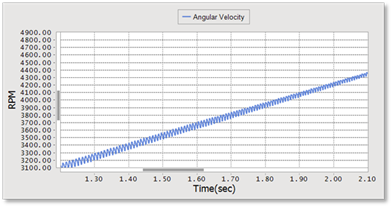

•Tacho Data

The tacho data represents the cyclic trigger signal for the completion of each rotation, in the form of one trigger to one cycle. When this data is inputted in the form of sine function, step function, or impulse function, RecurDyn’s Campbell process must convert it into RPMs before use.

Figure 2 Tacho data

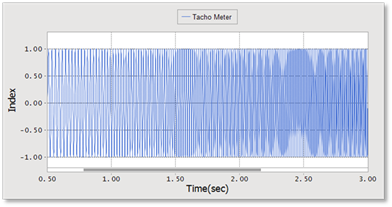

•Translating tacho data into RPM data

There are several ways to represent the tacho data: peak pulse, step pulse, offset step pulse, sine wave, etc.

Figure 1 Various representations of tacho data

To calculate the correct RPM for each signal type, perform the following steps:

① Calculate the RMS of the tacho data.

② Tacho data (n) = Tacho data (n) – RMS.

③ Extract the phase change data point (PCDP) (- to +).

④ Calculate the RPMs from the delta time.

⑤ To calculate the RPM value for one point, calculate the average of the RPM values from the time data for the previous PCDP and the next PCDP.

⑥ Finally, use linear interpolation of the calculated RPM values to determine the RPM values of the remaining data points.

The time data remains the same when the tacho signal is converted into the RPM data. After the data conversion, the process is the same as for the RPM data.

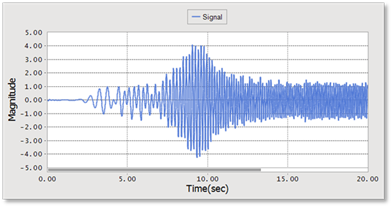

•Signal Data

About the tacho data and the RPM data: To measure the RPMs of a system during a test or simulation, the user should measure the speed and tachometer reading. When the user measures only the RPMs, the RPM value may also include high-frequency noise transmitted from the system. Therefore, the noise may influence the calculation of the RPM value for each frame. If the RPM response over time is relatively non-linear, then the influence of this noise may be even more pronounced. In contrast to this, the tacho data only measures the cycle for one rotation, so it automatically eliminates any influence from high-frequency noise. Therefore, it is better to use a sine or step function and produce the tacho data for a periodic function than to measure and use the RPM value.