Group

Plot Content

Outputs

Pos_

Position and Z-X-Z euler angles of the specified sheet bodies

Vel_

Velocity of the specified sheet bodies. The translational Velocity is measured in the global reference frame. The angular velocity is measured in the reference frame of sheet body (or nodal).

Acc_

Acceleration of the specified sheet bodies. The translational acceleration is measured in the global reference frame. The angular acceleration is measured in the reference frame of sheet body (or nodal).

_Contact

Contact forces generalized at a node. The force is measured in the reference frame of sheet body (or nodal).

Impulse

Impulse of contact forces (= |F|*dt)

_Elastic

Generalized elastic forces. This force is calculated from the element stiffness matrix and deformation of a node. The force is measured in the reference frame of sheet body (or nodal).

_Nodal

Generalized nodal forces at the specified node. If there is no nodal force on the node, the result is zero. The force is measured in the reference frame of sheet body (or nodal).

_Air_Resistance

Air Resistance Forces. If the Air Resistance Coefficient option is not checked, the result is zero. The force is measured in the reference frame of sheet body (or nodal).

EX,EY,EZ,EXY,EYZ,EZY

Strain tensor. The tensor is measured in the global reference frame. For more information, refer to Post process in FFlex.

E1,E2,E3

Principal strain. For more information, refer to Post process in FFlex.

EINT

Intensity strain. For more information, refer to Post process in FFlex.

EMISES

Von-Mises strain. For more information, refer to Post process in FFlex.

SX,SY,SZ,SXY,SYZ,SZY

Stress tensor. The tensor is measured in the global reference frame. For more information, refer to Post process in FFlex.

S1,S2,S3

Principal stress. For more information, refer to Post process in FFlex.

SINT

Intensity stress. For more information, refer to Post process in FFlex.

SMISES

Von-Mises stress. For more information, refer to Post process in FFlex.

Fixed Roller

MeanDPEN_SHT

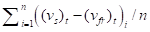

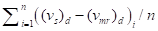

Mean value of the derivatives of a penetration with respect to the time of the contact normal direction at contact points between the roller and the sheet. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

MeanRvelT_SHT

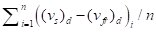

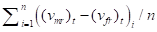

Mean value of the relative velocities in the contact tangent direction (parallel to the tangent direction of roller) at contact points between the roller and the sheet. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

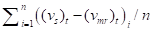

MeanRvelD_SHT

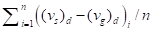

Mean value of the relative velocities in the contact tangent direction (parallel to the depth direction of roller) at contact points between the roller and the sheet. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

NormalF_SHT

Summation of forces in the contact normal direction at the contact points with the sheet.

FrictionFT_SHT

Summation of friction forces in the contact tangent direction (parallel to the tangent direction of roller) at the contact points with the sheet.

FrictionFD_SHT

Summation of friction forces in the contact tangent direction (parallel to the depth direction of roller) at the contact points with the sheet.

Contact_SHT

Contact forces generalized at the center of roller. The force is measured in the global reference frame.

Impulse_DT

Impulse of the driving torque for a revolute joint (= |T|*dt)

ContactPoints

The contact points data are written sorted by the bigger normal force. Each contact point data are 15 values includes contact position vector, normal direction vector, friction direction vector, penetration depth, penetration velocity, tangential relative velocity, friction coefficient, normal force, and friction force. The number of outputs is defined as the “No. of Max Contact Point” on the Contact page of the properties dialog.

Movable Roller

MeanDPEN_SHT

Mean value for the derivatives of a penetration with respect to the time of the contact normal direction at contact points between the roller and the sheet. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

MeanRvelT_SHT

Mean value of the relative velocities in the contact tangent direction (parallel to the tangent direction of roller) at contact points between the roller and the sheet. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

MeanRvelD_SHT

Mean value of the relative velocities in the contact tangent direction (parallel to the depth direction of roller) at contact points between the roller and the sheet. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

NormalF_SHT

Summation of forces in the contact normal direction at the contact points with the sheet.

FrictionFT_SHT

Summation of friction forces in the contact tangent direction (parallel to the tangent direction of roller) at the contact points with the sheet.

FrictionFD_SHT

Summation of friction forces in the contact tangent direction (parallel to the depth direction of roller) at the contact points with the sheet.

Contact_SHT

Contact forces generalized at the center of roller. The force is measured in the global reference frame.

MeanRevlT_FR

Mean value of the relative velocities in the contact tangent direction (parallel to the tangent direction of roller) at contact points between the movable roller and the fixed roller. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

NormalF_FR

Summation of forces in the contact normal direction at the contact points with the fixed roller.

FrictionFT_FR

Summation of friction forces in a contact tangent direction (parallel to the tangent direction of roller) at the contact points with the fixed roller.

Contact_FR

Contact forces generalized at the center of roller. The force is measured in the global reference frame.

MaxGap_NF

Contact normal force for the maximum gap.

SoftNip_NF

Contact normal force for the soft nip.

Impulse_DT

Impulse of the driving torque for a revolute joint (= |T|*dt)

ContactPoints

The contact points data are written sorted by the bigger normal force. Each contact point data are 15 values includes contact position vector, normal direction vector, friction direction vector, penetration depth, penetration velocity, tangential relative velocity, friction coefficient, normal force, and friction force. The number of outputs is defined as the “No. of Max Contact Point” on the Contact page of the properties dialog.

Line Guide

Arc Guide

Circular Guide

Sheet to Surface Contact

Sheet to Sphere Contact

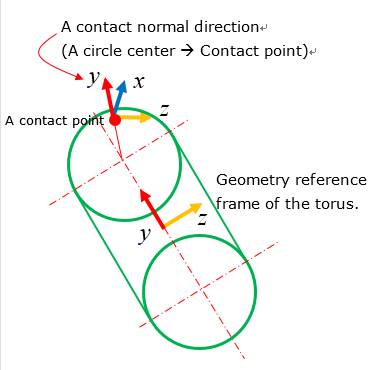

Sheet to Torus Contact

MeanDPEN_SHT

Mean value for the derivatives of a penetration with respect to the time of the contact normal direction at contact points between guide and sheet. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

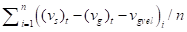

MeanRvelT_SHT

Mean value of the relative velocities in the contact tangent direction (parallel to the tangent direction of roller) at contact points with the sheet. The value is calculated as the following equation.

where,  is the number

of contact points. vgvel

is the Guide

Velocity.

is the number

of contact points. vgvel

is the Guide

Velocity.

MeanRvelD_SHT

Mean value of the relative velocities in the contact tangent direction (parallel to the depth direction of guides) at contact points with the sheet. The value is calculated as the following equation.

where,  is the number

of contact points.

is the number

of contact points.

NormalF_SHT

A scalar value and summation of magnitudes of contact normal force at all contact points.

FrictionFT_SHT

A scalar value and summation of magnitudes to tangential direction of contact friction force at all contact points.

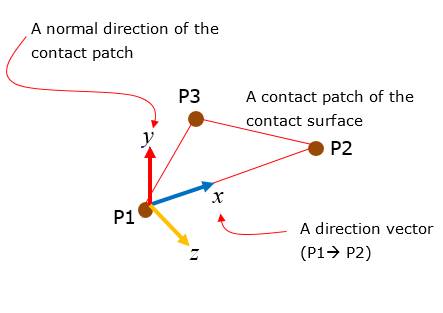

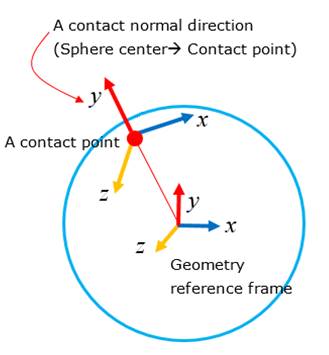

In the case of Sheet to Surface/Sphere/Torus contact, the tangent direction is specially defined for each contact case. Refer to the NOTE below this table.

FrictionFD_SHT

A scalar value and summation of magnitudes to depth direction of contact friction forces at all contact points.

In the case of Sheet to Surface/Sphere/Torus contact, the tangent direction is specially defined for each contact case. Refer to the NOTE below this table.

Contact_SHT

Contact forces between sheet and a guide or a rigid body. Reference frame of the force vector is the inertia marker of the ground body. In order to report, the summation of contact force is converted a force which is acting on the reference marker of the guide surface (Linear/Arc/Circular guide) or the CM marker of the rigid body (Sheet to surface/sphere/torus).

ContactPoints

The contact points data are written sorted by the bigger normal force. Each contact point data are 15 values includes contact position vector, normal direction vector, friction direction vector, penetration depth, penetration velocity, tangential relative velocity, friction coefficient, normal force, and friction force. The number of outputs is defined as the “No. of Max Contact Point” on the Contact page of the properties dialog.

Sensor

Speed Sensor

Speed of the closest sheet in the specified direction of the sensor.

Event Sensor

When a head or trail of sheet passes to the sensor, the result is 1, or not 0. Also, the user can know the time when the sheet goes to the sensor.

Distance Sensor

Distance of the closest sheet in the specified direction of the sensor.

Tension Sensor

Stress of the closest sheet in the sensor.