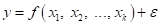

depends on the controllable

input variables

depends on the controllable

input variables  . The

relationship is

. The

relationship is

Response surface Method is an integration of

statistical and mathematical techniques useful for developing, improving, and

optimizing process. The most extensive applications of RSM are in the

industrial world, particularly in situations where several variables potentially

influence some performance measure or quality characteristics of the product or

process. In general, a product or system response  depends on the controllable

input variables

depends on the controllable

input variables  . The

relationship is

. The

relationship is

where, the form of true response function  is unknown and perhaps very complicated,

and

is unknown and perhaps very complicated,

and  is a term that

represents other sources of variability not included in

is a term that

represents other sources of variability not included in  . In general, the statistical error

. In general, the statistical error  is a normal distribution

is a normal distribution

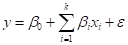

. Suppose that the linear

model

. Suppose that the linear

model  may be

represented by

may be

represented by

where, are

the unknown coefficients. If there is more than one data point under

consideration, the linear model is extended to the matrix form

are

the unknown coefficients. If there is more than one data point under

consideration, the linear model is extended to the matrix form

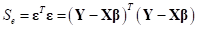

where  is a

vector of

is a

vector of  observations,

observations,  is a matrix of known

constant,

is a matrix of known

constant,  is a vector

of

is a vector

of  parameters, and

parameters, and  is the vector of random

errors. In order to obtain the unknown coefficients, we solve the sum of squares

of residuals as

is the vector of random

errors. In order to obtain the unknown coefficients, we solve the sum of squares

of residuals as  . To minimize

. To minimize

, we solve a set of

, we solve a set of  equations. Hence the normal

equation

equations. Hence the normal

equation  is obtained.

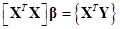

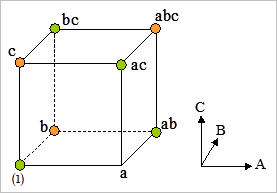

The matrix

is obtained.

The matrix  is a symmetric

matrix with

is a symmetric

matrix with  rows and

rows and

columns. Its rank is the same

as the rank of

columns. Its rank is the same

as the rank of  , which is the

number of linearly independent column of

, which is the

number of linearly independent column of  .

.

If the  columns of

columns of  are linearly independent,

are linearly independent,  exists and the normal

equations have a unique set of solutions

exists and the normal

equations have a unique set of solutions  . However, if

. However, if  is less than full rank because the

columns are not linearly independent,

is less than full rank because the

columns are not linearly independent,  is singular and

is singular and  does not exist. It will, in fact, be

true of almost the experimental design models. Hence special numerical

techniques are required to generalize the response surface modeling methods.

does not exist. It will, in fact, be

true of almost the experimental design models. Hence special numerical

techniques are required to generalize the response surface modeling methods.

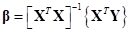

Figure 1 The geometric view of a  design

design