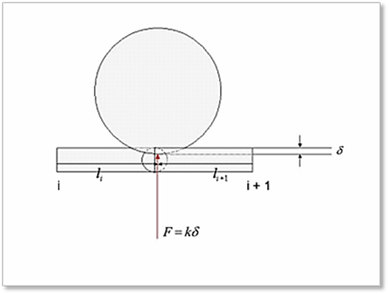

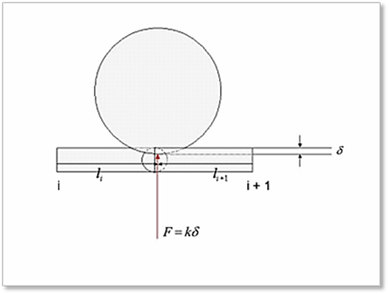

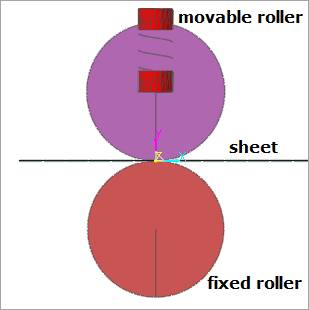

Figure 1 Contact force in the circular part of sheet

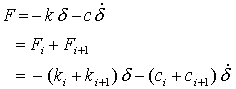

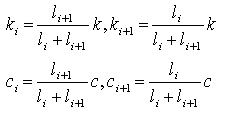

When a roller or a guide edge makes contact near a circular part of sheet segments, a contact force shows a tendency to increase due to double contacts. Consequently the results contain a noise with a frequency dependent on the length of the sheet segment. To reduce the double contact effect, the k and c coefficients are interpolated in the circular parts when computing the contact force. In this case, it is very important to balance the forces applied on two adjacent sheet bodies holding down the resultant contact force. As shown in Figure 1, the resultant contact forces are defined with the following equations.

(6)

(6)

(7)

(7)

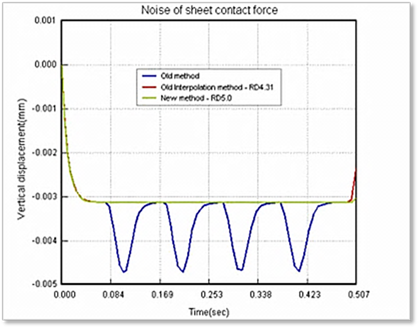

A sheet passes through a roller pair as shown in Figure 2. As shown in the plot in Figure 3, a relative displacement of a translation joint of a movable roller that is plotted in red line has a noise with a frequency in the previous versions. But the blue line shows that the noise is reduced in this current version.

Figure 2 Example model for noise problem

Figure 3 Advanced result of example model