CASE I. Tight Concave-Convex Contact Problems

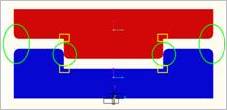

“Tight Concave-Convex Contact” problems are those problems where the surfaces in the contact region resemble the figure:

This kind of contact problem is very difficult to solve. Therefore if the results or performance is not good in the “Tight Concave-Convex contact problems”, try the guideline in the following procedures (Following is recommending guideline and will be very helpful to understand the Manual Mode of RecurDyn solid contact).

•Guideline 1. Use Automatic Option (This is a default option of the solid contact)

•Guideline 2. If the user cannot get the good result by Guideline 1, please use Detailed Contact Option.

•Change to Manual Mode for the GMP and LMP with Default Values.

•Guideline 3. If the user cannot get the good result by Guideline 1 and Guideline 2, please try to change the LMP Value.

•Increase the LMP Value (multiply the default LMP by the factor, 1.5 or 2.0)

•Decrease the LMP Value (multiply the default LMP by the factor, 0.7 or 0.5)

•Increase/Decrease the GMP value in the similar manner can improve the result.

•Guideline 4. If the user cannot get the good result by Guideline 1, Guideline 2 and Guideline 3, and if the friction of the contact is OFF, then please try to change the friction to ON. Friction can increase the stability of the contact model. When the user changes the friction to ON, please retry the first three guidelines again.

•Guideline 5. If the user still cannot get the reasonable solution, please try to change the model as shown in the figure. And please notice that 4 edges of yellow rectangle boxes are not rounded. If these 4 edges are rounded, this contact problem will be still the tight concave-convex contact problem”. (This approach is to avoid the tight concave-convex contact problem: This kind of process will help for the good solution in most cases.)

•Example for Tight Concave-Convex Contact Problem

Let’s consider this problem with following RecurDyn model. This example case is very difficult one. With the default values, this case cannot be solved. So we will follow the guidelines which were explained above.

•Model Definitions

|

- Bodies: Base Body is Blue (Lower), Action Body is Red (Upper). - Joint : Fixed Joint at Base Body - Contact: Between Base and Action Bodies. - Gravity exists. - Solving parameters are all default if not specified.

>> Default GMP = 147. >> Default LMP = 36.8 |

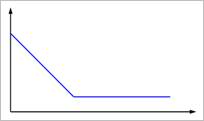

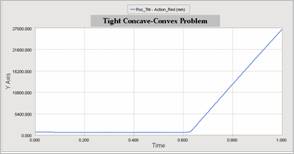

We will check the displacement of the action body (red). We expect that the red body will fall a little and after contacts, it will not fall further. So, the expected result will be as shown in the Figure:

Figure 1 Expected result

•Guideline 1. Use Automatic Option (This is a Default Option)

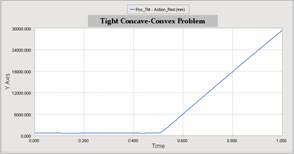

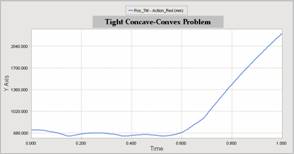

Figure 2 Result of the Guideline 1

Comments> The result is unreasonable. The action body bounced off at about 0.5 s. Go to the Guideline 2.

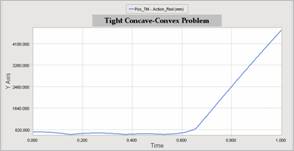

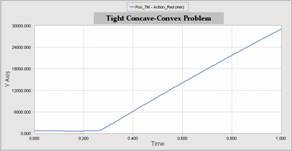

•Guideline 2. Change to Manual Mode for the GMP and LMP with Default Values. Result with GMP = 147. , LMP = 36.8 (These are Default Values)

Figure 3 Result with the Guideline 2

Comments> The result is better than the result of Guideline 1 but still unreasonable. Go to the Guideline 3.

•Guideline 3. Change the LMP Values

o Increase the LMP Value with factor 1.5 or 2.0

o Decrease the LMP Value with factor 0.7 or 0.5

Figure 4 Result with LMP = 73.6 (36.8x2)

Comments> The result get worse with the bigger LMP. So we tried the less LMP

Figure 5 Result with LMP = 18.4 (36.8x0.5)

Comments> The result get improved a little. But the result is still unreasonable. Therefore go to the Guideline 4. (Before going to Guideline 4, the user can also try for the GMP value change)

•Guideline 4. Since the friction is OFF in this model, we will use the Friction ON.

Figure 6 Result with default Friction and Guideline 1 (Automatic Mode)

Comments> The result is not good. And we can know that in case of ‘tight concave-convex problem’, using ‘manual mode’ is usually better. Therefore, let’s use manual mode with Friction.

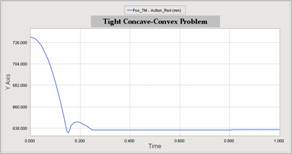

Figure 7 Result with Default Friction and Guideline 2(Manual Mode with default LMP&GMP)

Comments> Now, The result is reasonable!

CASE II: Wide Surface Contact Problems

Wide surface means that the surface area in contact region is wide or large.

As the user already noticed out, the “Tight Concave-Convex Contact Problem” is a special case of the “Wide Surface Contact Problems”. Therefore the guidelines for the “Tight Concave-Convex Contact Problem” explained above can be used in “Wide Surface Contact Problems” similarly. (We don’t include the example case for case II because it is almost similar to the case I).