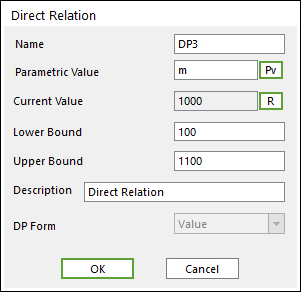

1. Direct Relation

One can define the relationship between the design variable and the parametric value. AutoDesign change the value of design variables in its processes. Then, the parametric values linked by this option are internally changed. Finally, analysis parameters modeled by these parametric values are sequentially changed. Figure 1 shows the sequence of these relations.

Figure 1 Direct Relation dialog box

•Parametric Value: ‘Pv’ button change the dialogue as ‘Parametric Value List’. Then one can select the parametric value related design variable.

•Current Value: ‘R’ button can refresh the parametric value.

•‘Lower Bound’, ‘Upper Bound’: The boundary of the defined design parameter.

•Description: One can describe the design variable in the ‘Description’ blank.

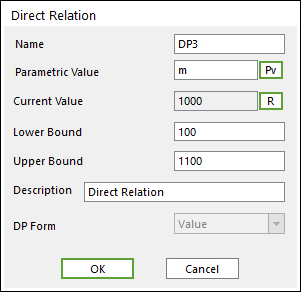

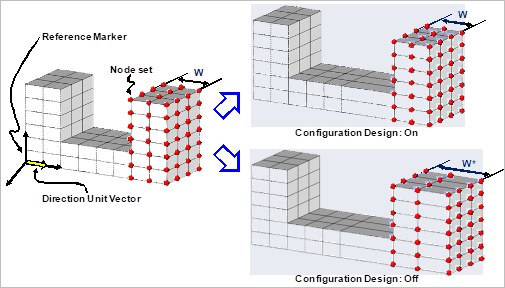

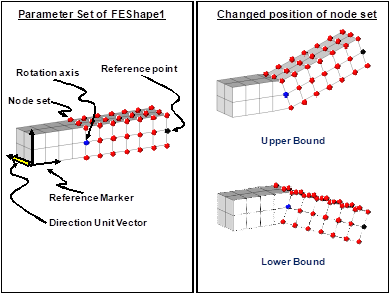

2. FEShape1: Translation Relation

As shown in Figure 2, one wants to change the initial position of node set. Then, he uses this design variable type.

Figure 2 FEShape1: Translation Relation

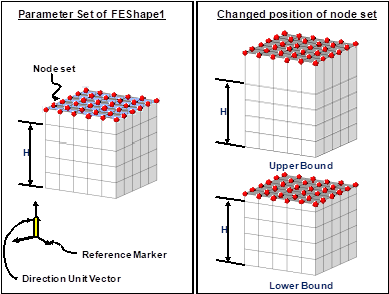

Figure 3 FEShape1: Translation Relation dialog box

•Node Set: One can define the node set in the blank or navigate from window using ‘N’ button.

•Configuration Design: you can select ‘on’ or ‘off’. For example, if you select ‘on’, node set-A is moved as figure 4. It is note that the relative positions are maintained among nodes in the node set but their global position is moved. If you select ‘off’, node set-A is moved as figure 4. Their relative positions and global positions are changed simultaneously. The default option is ‘off’.

Figure 4 The role of configuration design switch

•Reference Marker: Allows you to write the name of the reference marker in the blank or navigate from window using the ‘M’ button. This is the reference mark to measure the distance of node set.

•Directional Unit Vector: One can define unit vector in the blank or navigate from window using ‘D’ button. This is the direction of changing the shape of node set.

•Current Value: ‘1’ is the scale factor represented the original position. All positions of the node set are measured from the reference coordinate. Then, these values are saved the current positions of node set. As all nodes have different positions, the scale factor is employed for design variable.

•‘Lower Bound’, ‘Upper Bound’: The lower and upper bound of the

scale factor of node positions. Suppose that Lower and upper bounds are defined

as 0.7 and 1.3 respectively. Then, during the optimization process, the

positions of the selected node set can be changed during

•Description: One can describe the design variable in the ‘Description’ blank.

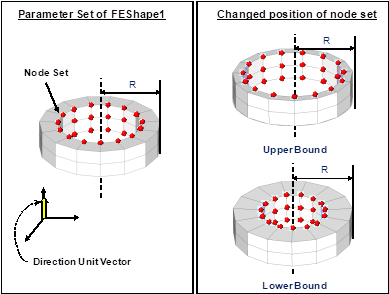

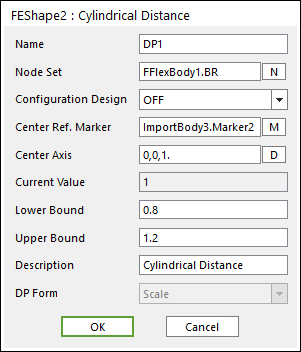

3. FEShape2: Cylindrical Distance

As shown in Figure 5, this design variable type can change the position of node set along the radial direction. To do this, one selects the node set and define the reference mark and the center axis. Then, he defined the lower and upper bounds of the position scale factor.

Figure 5 FEShape2: Cylindrical Distance

Figure 6 FEShape2: Cylindrical Distance dialog box

•Node Set: One can define the name of the node set in the blank or navigate from window using ‘N’ button.

•Configuration Design: This switch should be ‘off’. The relative positions are not maintained along the radius direction. If one wants to move the node set radial direction, he can use the translation relation.

•Center Ref. Marker: One can define the name of the reference marker in the blank or navigate from window using ‘M’ button.

•Center Axis: One can input unit vector in the blank or navigate from window using ‘D’ button. The radial distance of node set is measured from this axis at the center reference marker.

•Current Value: ‘1’ is the scale factor represented the original position. All positions of the node set are measured from the reference axis. Then, these values are saved the current positions of node set. As all nodes have different positions, the scale factor is employed for design variable.

•‘Lower Bound’, ‘Upper Bound’: The lower and upper bound of the scale factor of node positions. Suppose that Lower and upper bounds are defined as 0.7 and 1.3 respectively. Then, during the optimization process, the positions of the selected node set can be changed during ± 30 % of the current position along the radial directions from the center axis.

•Description: One can describe the design variable in the ‘Description’ blank.

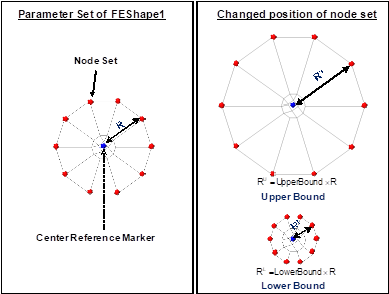

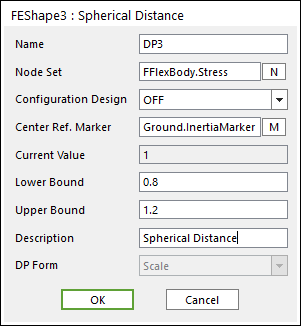

4. FEShape3: Spherical Distance

As shown in Figure 7, the positions of nodes can be changed along the radial directions from the center point of the reference marker. Suppose that one wants to change the ball bearing shape. Then, he can use this design variable type. First, he defines the node set for shape optimization. Next, he defines the center reference marker and the lower and upper bound of position scale factor.

Figure 7 FEShape3: Spherical Distance

Figure 8 FEShape3: Spherical Distance dialog box

•Node Set: One can define the name of the node set in the blank or navigate from window using ‘N’ button.

•Configuration Design: This switch should be ‘off’. The relative positions are not maintained along the radius direction. If one wants to move the node set radial direction, he can use the translation relation.

•Center Ref. Marker: One can write the name of the reference marker in the blank or navigate from window using ‘M’ button.

•Current Value: ‘1’ is the scale factor represented the original position. All positions of the node set are measured from the reference point. Then, these values are saved the current positions of node set. As all nodes have different positions, the scale factor is employed for design variable.

•‘Lower Bound’, ‘Upper Bound’: The lower and upper bound of the scale factor of node positions. Suppose that Lower and upper bounds are defined as 0.7 and 1.3 respectively. Then, during the optimization process, the positions of the selected node set can be changed during ± 30 % of the current position along the radial directions from the center point.

•Description: One can describe the design variable in the ‘Description’ blank.

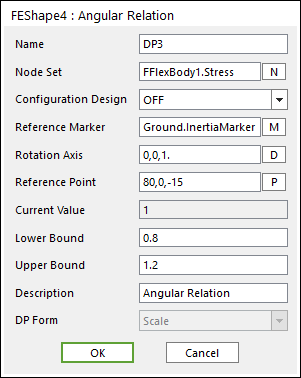

5. FEShape4: Angular Relation

As shown in Figure 9, the position of node set can be rotated. The positions of node set are rotated from the reference plane at the reference marker.

Figure 9 FEShape4: Angular Relation

Figure 10 FEShape4: Angular Relation dialog box

•Node Set: One should define the name of the node set in the blank or navigate from window using ‘N’ button.

•Configuration Design: When you select ‘on’, the selected node set are rotated and maintained the relative distance which is shown in Figure 3.1.2-10. Otherwise, their relative positions are changed from the reference plane. The default option is ‘off’.

•Reference Marker: One should write the name of the reference marker in the blank or navigate from window using ‘M’ button.

•Rotation Axis: One can input unit vector in the blank or navigate from window using ‘D’ button.

•Reference Point: One should define the position of the point in the blank or navigate from window using ‘P’ button. The reference plane is determined by using the rotation axis and this reference point.

•Current Value: ‘1’ is the scale factor represented the original position. All angles of the node set are measured from the reference plane. Then, these values are saved the current positions of node set. As all nodes have different angles, the scale factor is employed for design variable.

•‘Lower Bound’, ‘Upper Bound’: The lower and upper bound of the scale factor of node positions. Suppose that Lower and upper bounds are defined as 0.7 and 1.3 respectively. Then, during the optimization process, the positions of the selected node set can be rotated during ± 30 % of the current position from the reference plane.

•Description: One can describe the design variable in the ‘Description’ blank.