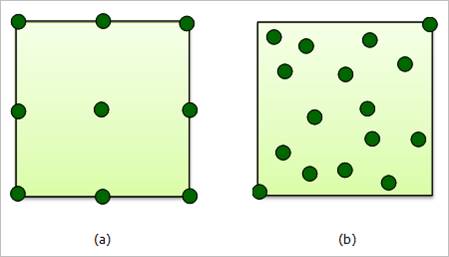

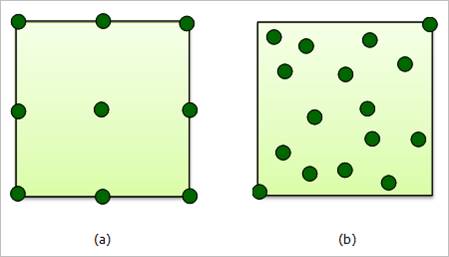

AutoDeisgn requires the initial DOE sampling for constructing meta-models. Thus, the lower and upper bounds on each design variable are automatically set from the initial DOE sampling range. Figure 1 shows the initial sampling points. The green points are the sampled design points of which analyses are succeeded in RecurDyn.

Figure 1 Design ranges in case that all analyses are succeed

Then, the solid box is automatically set to the design range during optimization process.

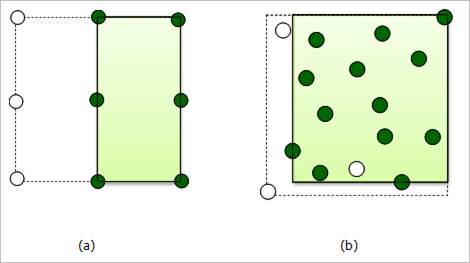

Figure 2 shows another sampling result. The white points denote the failure of analysis. In Figure 2 (a), the analyses are failed in the left sided points. In this case, AutoDesign neglects the left side points. Thus, the design range is reduced the solid box. Next, Figure 2 (b) shows another case of the initial sampling points. In this case, two points in the left side are failed. Thus, AutoDesign reduces the design range.

Figure 2 Design range in case that some analyses are failed

If the case (a) is occurred when you use AutoDesign, the design optimization can be failed because there is no feasible region. In this case, you should check the validity of performance indexes and their expressions. If all expressions have no problem, then you cannot help reducing the design ranges. In this case, the discrete Latin-hypercube method is recommended for the initial DOE show in Figure 2 (b).