In general, standard deviation is the best measure of process

or design variability because the smaller the standard deviation, the less

variability in them. If one can reduce sigma  , to the point that the specifications are

at

, to the point that the specifications are

at  , then

, then  of the product or design will be

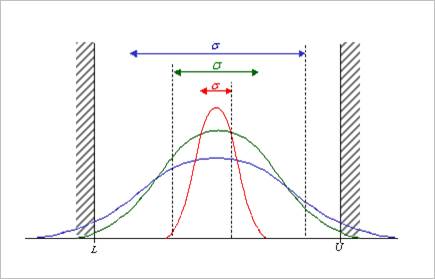

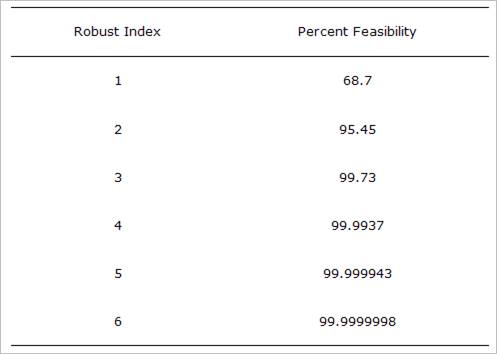

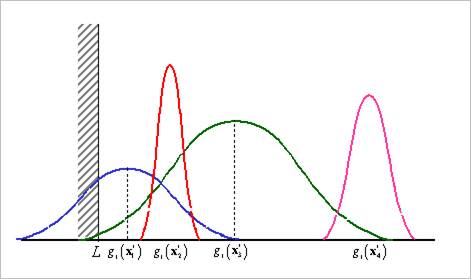

between specifications. Figure 1 shows the feasibility of both sided inequality

constraints. Suppose that three colored distributions have same center but

different sigma. If one distribution satisfies the relation of

of the product or design will be

between specifications. Figure 1 shows the feasibility of both sided inequality

constraints. Suppose that three colored distributions have same center but

different sigma. If one distribution satisfies the relation of  , then we say that it satisfies 6-sigma constraints.

, then we say that it satisfies 6-sigma constraints.

Figure 1 Feasibility of several distributions with same

centers

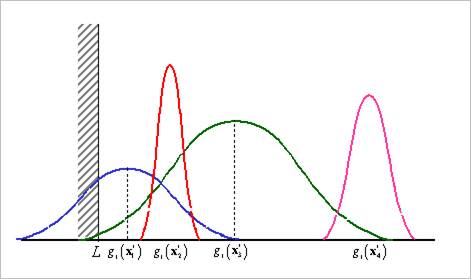

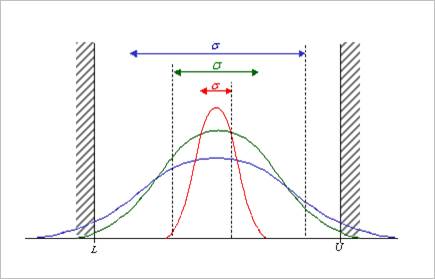

In the practical design, the inequality constraints have only

one-side limitation such as equation (4) in “Robust Design Optimization”.

Figure 2 shows the feasibility of several distributions with shifted centers. If

you change the design variables  , the mean and variance of a performance

, the mean and variance of a performance

will be changed, even

though all design variables have same variations

will be changed, even

though all design variables have same variations  .

.

Figure 2 Feasibility of several distributions with

shifted centers

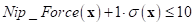

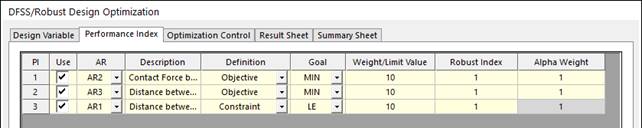

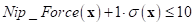

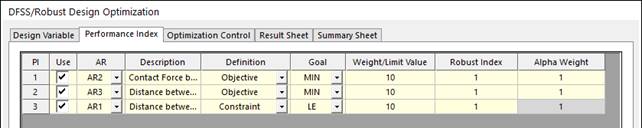

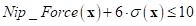

Next, the definition method of 6-sigma is explained. In the

Robust Design Optimization window, PI should be defined as

Constraint. Then, its goal is selected from LE or GE types.

In the following figure, Nip spring force is selected as LE type constraint.

Also, its value should be less than 10. The robust index is defined as “1”. In

AutoDesign, this inequality constraint is represented as:

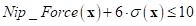

If one defines the robust index as “6”, then the nip force

constraint is 6-sigma constraint as

.

.

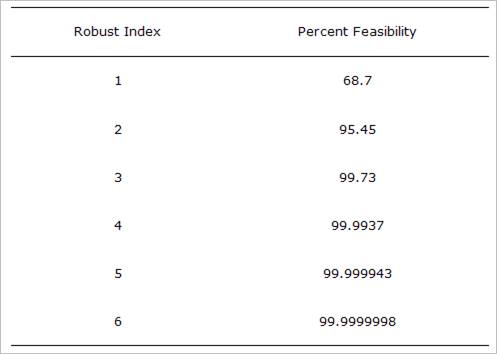

As you define the robust index between 0 ~ 6, the percent

feasibility will be changed. Table 1 shows the percent between robust index and

the feasibility of inequality constraints.

Table 1 Percent feasibility for robust formulation

, to the point that the specifications are

at

, to the point that the specifications are

at  , then

, then  of the product or design will be

between specifications. Figure 1 shows the feasibility of both sided inequality

constraints. Suppose that three colored distributions have same center but

different sigma. If one distribution satisfies the relation of

of the product or design will be

between specifications. Figure 1 shows the feasibility of both sided inequality

constraints. Suppose that three colored distributions have same center but

different sigma. If one distribution satisfies the relation of  , then we say that it satisfies 6-sigma constraints.

, then we say that it satisfies 6-sigma constraints.

, the mean and variance of a performance

, the mean and variance of a performance

will be changed, even

though all design variables have same variations

will be changed, even

though all design variables have same variations  .

.

.

.