Sometimes one design optimization problem has multiple solutions. Even though mathematical problems can give multiple solutions, practical designers want to select one of the multiple solutions. In order to help their selection, AutoDesign provides the design cost concept.

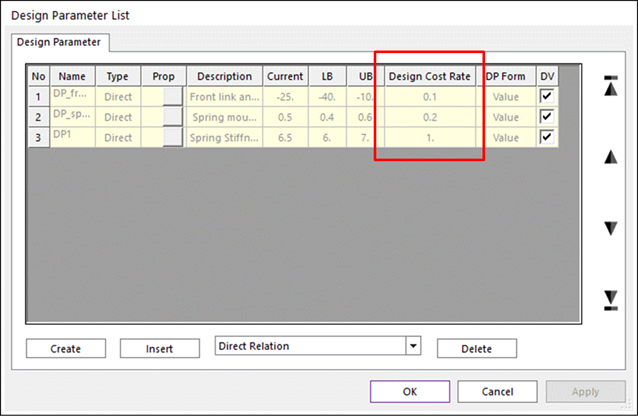

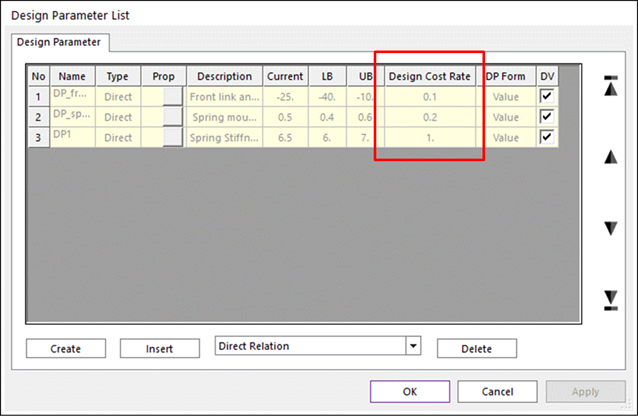

When one defines design parameters, he or she should define the design cost rate each design parameter shown in Figure 1. The value of design cost rate can be determined by material cost, manufacturing cost, operating cost etc. In other words, the designer regards them as the relative cost or efforts for design change.

Figure 1 Defining the design cost rates

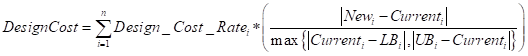

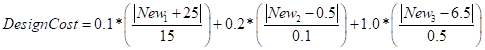

Then, AutoDesign evaluates the total design cost as follows:

Where ‘Current’, ‘LB’, and ‘UB’ denote the current value, the lower bound and the upper bound, respectively. ‘New’ is the changed value for the design parameter during optimization or effect analysis process.

Let’s consider the design cost for the sample shown in Figure 1.

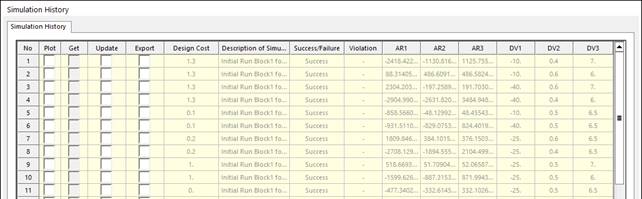

The evaluation results of design costs list in ‘Simulation History’ menu. Figure 2 shows a sample of result. The design cost of the 11th run shows ‘0’, because all DVs are current values.

Figure 2 Simulation history after meta-model construction

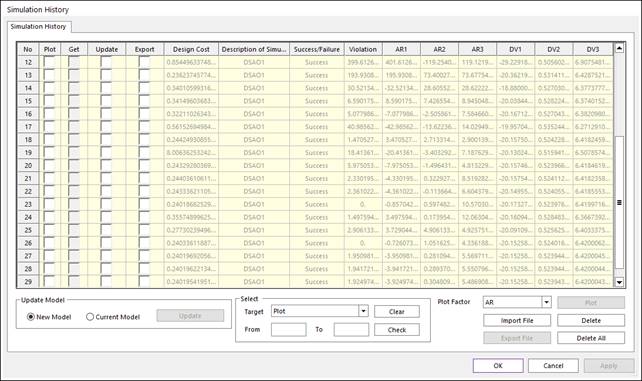

Now, let’s consider the simulation history after design optimization, which is shown in Figure 3. Only 2 runs such as 23rd and 26th are feasible solutions because their violations are ‘0’. As the goal of this design problem is to minimize AR3, the 23rd run is better than 26th one. Also, the design cost of the 23rd is much better than the 26th one. For this case, the design can select the 23rd design for saving money.

Figure 3 Simulation history after design optimization